DuraPack Python Side Loader

Durable. Fast. Smooth. The high-performance side-load garbage truck.

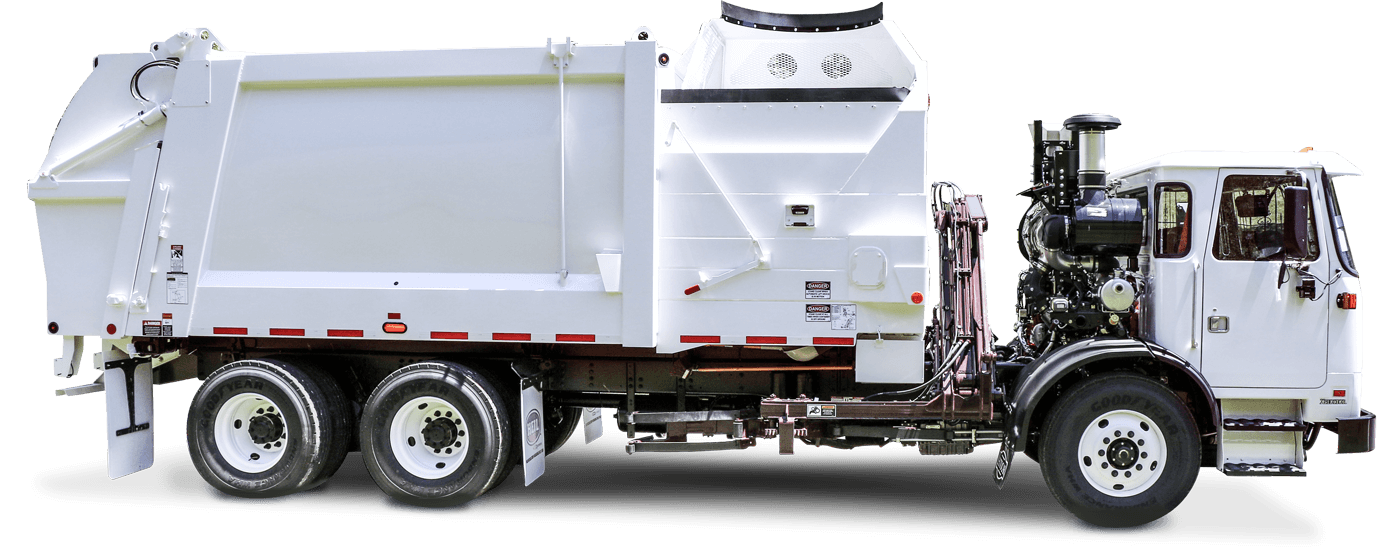

The DuraPack® Python® automated side loader combines two proven products in one high-performance package. The DuraPack side load body, which is famous for its toughness and productivity, and the patented Python automated arm, which is one of the fastest, smoothest, and longest-lasting lift arm combine to deliver proven performance and efficiency on residential waste collection routes.

OPTIONAL 3RD EYE DIGITAL PACKAGES

Connect your DuraPack Python sideload garbage truck and other vehicles in your fleet for service verification, body/chassis data, fuel tax reporting, and route management. Includes factory installed 3rd Eye® Mobile, Radar System, and the ability to connect up to six cameras.

DuraPack Python Automated side loader Standard Features

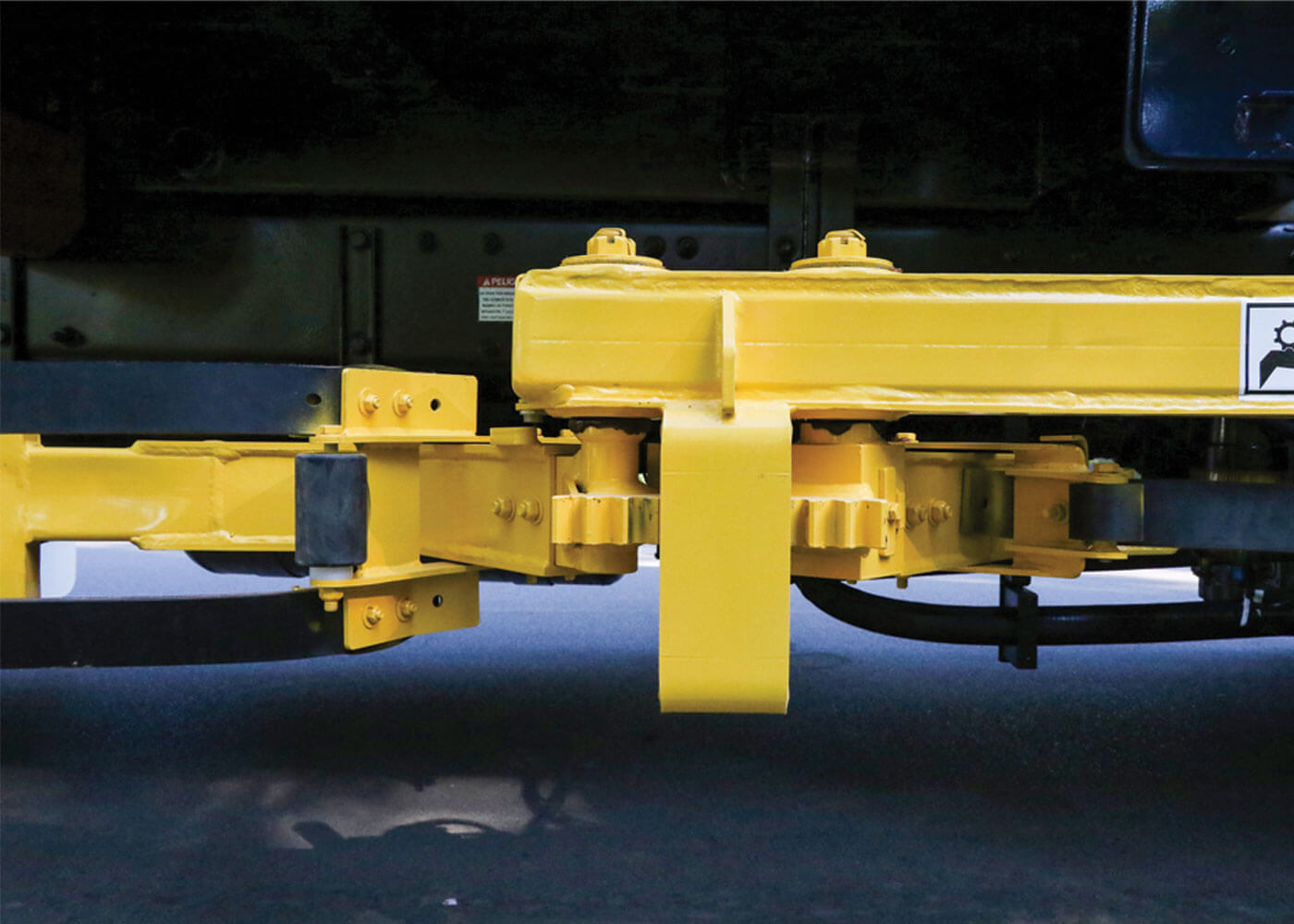

Our exclusive, fully welded, interlaced subframe provides exceptional longevity, while resisting abrasion, corrosion, and salt damage. The body is constructed of 7-8 ga. high tensile strength steel, while the hopper features 1⁄4″ thick AR400 steel on the floor, and 3⁄16″ thick AR400 steel on the sides for superior strength and durability.

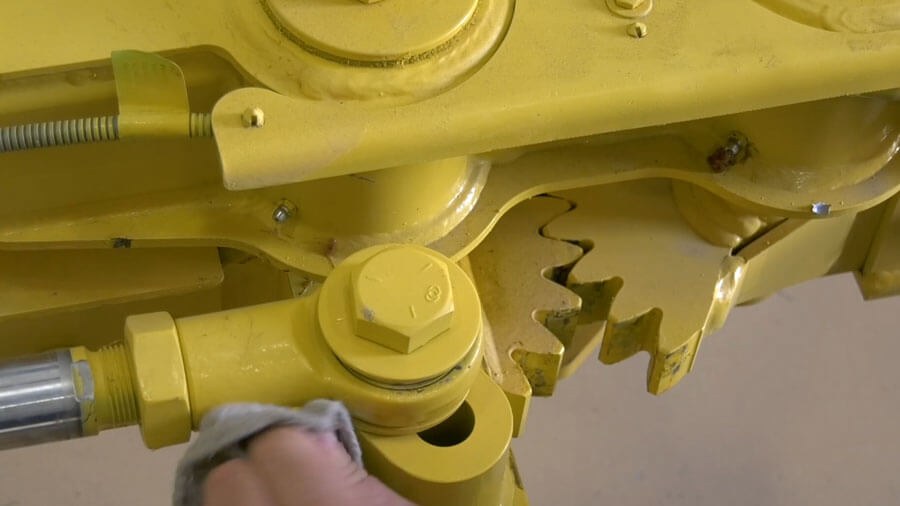

Made from specially formulated high-strength alloy steel, the Python lift arm’s superior hardened grabber gears virtually eliminate gear wear. The gears are splined to the grabber shafts and can be cycled up to 1,000,000 times with little evidence of wear.

Reliable, ergonomic joystick controls deliver smoother performance and enhanced usability. With the Auto-Lift system, the operator can reach, grab, lift, dump, and return the arm to the stowed position using only the joystick and 2 buttons.

With one of the fastest lift-cycle times in the refuse industry, the DuraPack Python will save time on route that can equate to fiscal savings of more than $15,000 per truck every year! The Python lift arm’s nine-foot reach can slither between cars and other obstacles, making even the most difficult pick-ups possible.

The DuraPack Python is brilliantly designed to have an optimized weight, without sacrificing strength and durability. The result is a perfect combination of dependability and increased payload. Greater route productivity delivers the lowest Total Cost of Collection (TCC).

High tensile strength steel withstands the exceptional forces of the compaction cycle, ensuring maximum payloads, and fewer trips to the disposal site.

The patented automated Python arm can reach up to nine feet to go where other automated arms cannot. Able to lift up to up to 800 pounds, the Python arm features cushioned cylinders for smooth action, saving wear and tear on both the lift arm and the chassis. The Python arm’s unique lift geometry enables the arm to consistently return carts with the lids closed.

Quickly and easily diagnose problems away from outside hazards and weather. On-board diagnostic tools make troubleshooting a breeze.

The DuraPack Python tailgate is reinforced to prevent buckling and features a 60″ seal to keep liquids inside the body where they belong.

The Heil in-cab operated tailgate locking system not only keeps payloads secure but also enables the operator to unlock and open the tailgate to discharge the payload from the safety and comfort of the cab. Reflective indicator tags, visible from the cab’s mirrors, confirm when the tailgate is sealed.

The “brain” of our system is the rugged mobile controller. This brilliant innovation provides unbeatable intelligence and precise control. Placing the mobile controller in a protected location gives us the intelligence we need and the durability our customers demand. This results in less downtime, ease of service, and unmatched simplicity of operation.

The Heil DuraMount Design, used to mount the lift to the chassis frame, reduces the potential for bolt fatigue, and provides Service Smart bolt access for easy maintenance.

THE POWER OF Connected collections

Fleets face continued frustration around their ability to connect with their customers. Fleet owners need better tools to communicate with their drivers – to ensure customer needs are met – while also ensuring they are operating efficiently… and safely. Introducing Connected Collections from Environmental Solutions Group companies, Soft-Pak®, Heil, and 3rd Eye. Together, we’ve developed Connected Collections to help fleet owners make better decisions faster.

DuraPack Python Optional Features

CNrG Tailgate

The lower profile, fully integrated CNrG tailgate fuel delivery system will revolutionize the way you use CNG garbage trucks.

Integrated lift camera and light

This integrated package provides the operator an exceptional view of the lift and surrounding environment.

3rd Eye Collision Avoidance Radar

3rd Eye family of Integrated Collision Avoidance Radar Systems protects both your drivers, your assets, and those in close proximity to your vehicle using existing 3rd Eye Mobile camera cables.

GENUINE OEM GARBAGE TRUCK PARTS

Heil Certified OEM parts are the most reliable replacement parts for Heil refuse collection vehicles. They’re made following the exact specifications and production processes on the same assembly lines as the parts originally installed on the bodies. This means that they fit perfectly every time. Heil uses only the highest-quality materials for parts that last – minimizing costly downtime. For more information on parts, contact your Heil dealer.

DuraPack Python RESOURCES

Nexteligence® Connected-Tech Training, where knowledge and technology meet. Designed to increase the knowledge and capabilities of Service Technicians for the Heil Product Line.